Think of your inventory as cash sitting on your shelves. Every bottle of wine, every side of beef, and every bag of flour is all capital just waiting to be converted.

The inventory days on hand (DOH) formula (Average Inventory ÷ Cost of Goods Sold) × Number of Days tells you exactly how long that cash stays tied up on a shelf before it turns into a sale. Getting a handle on this metric is one of the fastest ways to improve your cash flow and build a healthier restaurant.

Why the Inventory Days on Hand Formula Matters

In the controlled chaos of a restaurant, everything in your walk-in represents a financial bet. Your storeroom isn’t just a place for ingredients; it’s a vault holding your working capital. The longer an item sits there unsold, the more it costs you in tied-up funds, precious storage space, and the ever-present risk of spoilage.

This is where the DOH formula becomes one of your most practical financial tools.

It’s a simple calculation that reveals the average number of days it takes to sell through your entire inventory. It gives you a clear, honest snapshot of your operational efficiency. Are you turning products quickly, keeping cash moving? Or are your funds getting stuck on the shelves for too long? Answering this question is the first step toward running a smarter, more profitable operation. You can learn more about building a profitable business with our ultimate checklist for running a profitable restaurant in 2025.

Understanding the Formula Components

The DOH concept isn’t just for restaurants; it is a cornerstone of supply chain management that helps businesses everywhere balance having enough stock with the cost of holding it. For instance, some U.S. retailers typically carry inventory for around 30 to 60 days, with grocers tending toward the lower end of the range and consumer-electronics stores often at the higher end.

To calculate your own DOH, you first need to get comfortable with the three key parts of the formula.

Breaking Down the DOH Formula Components

Here’s a quick look at each piece of the puzzle and why it matters for your restaurant.

| Component | What It Measures | Why It Matters for Your Restaurant |

|---|---|---|

| Average Inventory | The average value of your inventory over a specific period. | This smooths out the peaks and valleys from big deliveries or slammed weekends, giving you a more realistic picture of your typical stock levels. |

| Cost of Goods Sold (COGS) | The direct cost of all the food and beverage ingredients you actually sold during that same period. | This represents the value of inventory that left the building and generated revenue. It’s the “sold” part of the equation. |

| Number of Days | The timeframe you’re analyzing, usually a month (30) or a quarter (90). | This sets the period for your calculation, ensuring your DOH metric is consistent and comparable over time. |

Once you’ve mastered these inputs, you can calculate an accurate DOH that gives you real insight into your operation. To go even deeper, it’s worth exploring other essential inventory management formulas in Excel that can paint an even clearer picture of your financial health.

Calculating Your Average Inventory and COGS

Before you can get a clear picture of your inventory days on hand, you need to nail down two key numbers: your Average Inventory and your Cost of Goods Sold (COGS). Think of them as the foundational ingredients in a recipe. If they’re off, the final dish just will not work.

Let’s walk through how to calculate each one so you can trust the numbers you’re working with.

Finding Your Average Inventory

Your inventory is always in flux. One day you get a big delivery, and the next you have a blowout service that clears the shelves. Average Inventory smooths out these peaks and valleys, giving you a much more stable snapshot of your typical stock value over a set period.

The formula itself is simple:

Average Inventory = (Beginning Inventory + Ending Inventory) / 2

To get these numbers, you’ll need to do a physical inventory count at the start and end of your chosen period. For most restaurants, this means monthly. Just add the total dollar value of your starting inventory to the value of your ending inventory, then divide that by two.

- Beginning Inventory: The total value of all food and drinks on your shelves on day one (e.g., May 1).

- Ending Inventory: The total value of everything left on the last day of that same period (e.g., May 31).

Getting this right is the first crucial step.

As you can see, solid inventory and COGS data are the bedrock of an accurate DOH calculation. No shortcuts here.

Calculating Your Cost of Goods Sold

Next up is your Cost of Goods Sold, better known as COGS. This is not just what you spent on inventory; it’s the direct cost of only the ingredients that were actually sold to customers during that same period. It specifically leaves out anything still sitting on your shelves.

The formula for COGS is just as straightforward:

COGS = Beginning Inventory + Purchases – Ending Inventory

You take your starting inventory value, add the cost of all the new inventory you bought during the month, and then subtract the value of what you had left at the end. The number you are left with is the precise cost of the products that went into the dishes and drinks that your guests paid for.

Let’s run the numbers for a bar’s COGS in May:

- Beginning Inventory (May 1): You kick off the month with $10,000 worth of liquor, wine, and beer.

- Purchases: Over the course of May, you order and receive an additional $8,000 in bar stock.

- Ending Inventory (May 31): After your end-of-month count, you find you have $9,000 worth of inventory remaining.

Plugging this into the formula: $10,000 + $8,000 – $9,000 = $9,000.

Your bar’s COGS for the month was $9,000. Now you have both pieces of the puzzle, your Average Inventory and your COGS, and you’re ready to calculate your days on hand.

Putting the Inventory Days on Hand Formula to Work

Alright, you’ve done the hard work of calculating your Average Inventory and Cost of Goods Sold. Now for the fun part. This is where those numbers stop being data points on a spreadsheet and start telling you a story about your restaurant’s health.

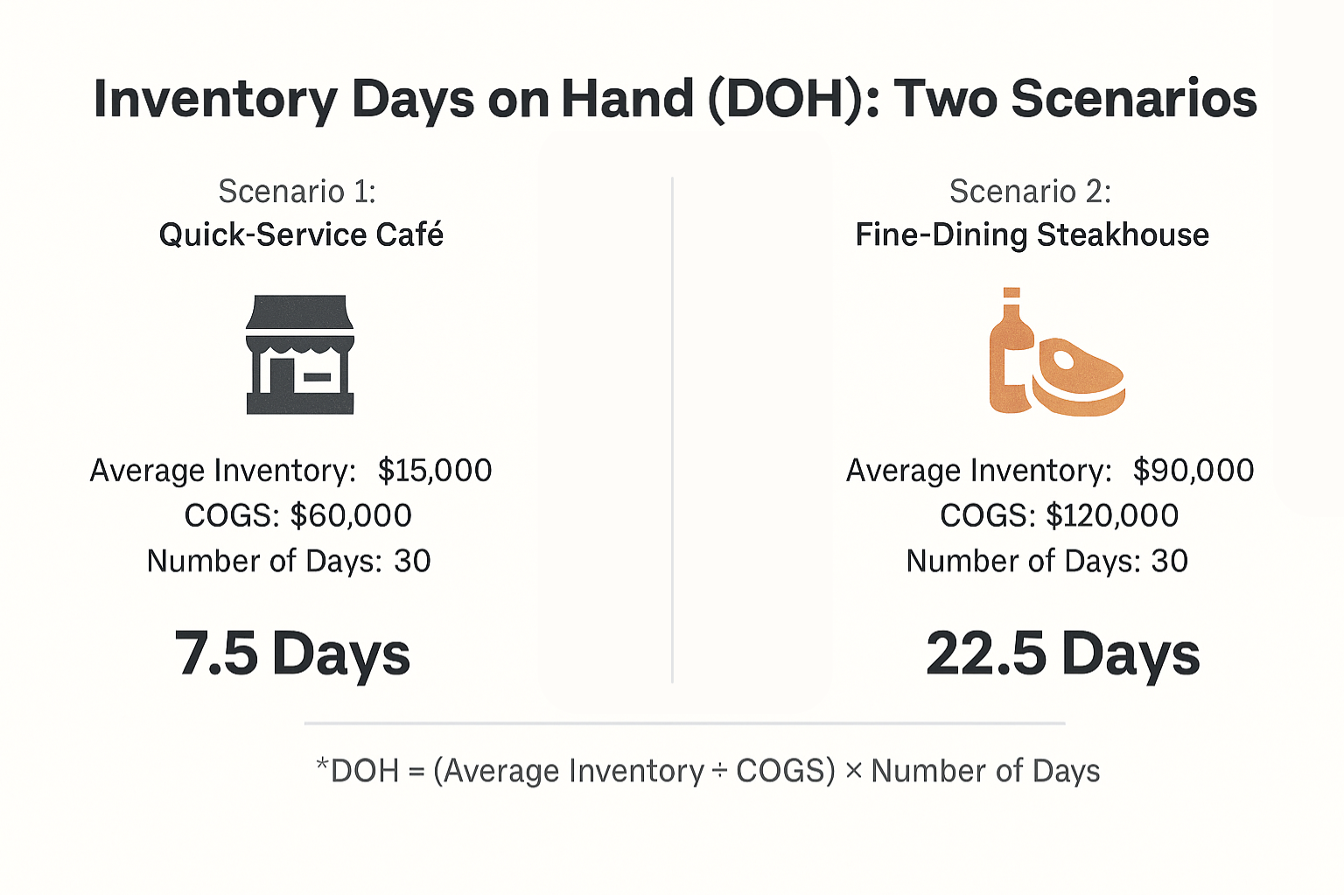

Let’s walk through how to apply the formula in two completely different restaurant settings. You’ll see right away how different business models create vastly different, but equally valid, DOH results. This is key to figuring out what a “good” number looks like for your specific operation.

Scenario One: The Quick-Service Cafe

Picture a bustling downtown cafe. They’re serving coffee, sandwiches, and pastries all day long, built on a model of high volume and lightning-fast turnover. Fresh items like bread, milk, and produce are coming in the door almost daily. Their entire game is about keeping just enough on hand to power through a busy lunch rush without anything going bad.

Here are their numbers for June, a 30-day period:

- Average Inventory: $15,000

- Cost of Goods Sold (COGS): $60,000

- Number of Days: 30

Now, let’s plug these into the inventory days on hand formula:

DOH = (Average Inventory / COGS) × Number of Days

DOH = ($15,000 / $60,000) × 30

DOH = 0.25 × 30 = 7.5 days

The cafe’s DOH is 7.5 days. That means, on average, they hold just over a week’s worth of product before it’s sold. For a business that lives and dies by freshness and speed, that lean number is a huge win. It is a sign of a tight, efficient operation.

Scenario Two: The Fine-Dining Steakhouse

Now, let’s pivot to an upscale steakhouse. They’re known for beautifully aged, prime cuts of beef and an extensive wine cellar. Their inventory is much more expensive, and it moves a whole lot slower than the cafe’s. That prime beef has to age for weeks to be perfect, and some of those rare wines might sit in the cellar for months.

Here’s what their books look like for that same 30-day stretch:

- Average Inventory: $90,000

- Cost of Goods Sold (COGS): $120,000

- Number of Days: 30

Let’s run the formula again:

DOH = ($90,000 / $120,000) × 30

DOH = 0.75 × 30 = 22.5 days

The steakhouse’s DOH is 22.5 days. That number is nearly three times higher than the cafe’s, but it is not a red flag. It is a direct reflection of their business model. They need to invest heavily in that slow-moving, high-cost inventory to deliver the premium experience their guests pay for.

This calculation should be a regular part of your financial check-ins, something you build right into your operational workflow. If you need help documenting these kinds of processes, it’s worth checking out some solid restaurant standard operating procedures examples.

These two scenarios drive home a critical point: a “good” DOH is completely relative. The lean inventory that makes the cafe successful would put the steakhouse out of business, and vice versa. The real power here isn’t about hitting some magic number. It is about using the formula consistently to see your own trends, spot problems early, and make smarter decisions for your restaurant.

What Your DOH Number Is Telling You

So, you have calculated your Days on Hand. That’s a solid first step, but a number floating in space is just data. The real magic happens when you understand the story that number is telling you about your restaurant’s cash flow and kitchen efficiency.

Think of your DOH as a measure of the balance between what you buy and how fast you sell it. It is telling you, on average, exactly how long your cash is sitting on shelves as inventory before your team turns it back into revenue.

The Story Behind a High DOH

A high DOH number means your inventory is moving slowly. For a steakhouse aging prime cuts or a wine bar cellaring special vintages, that might be intentional. But for most spots, it is a big red flag. A high DOH often means too much cash is tied up in stock that is not making you money.

Worse, it cranks up the risk of spoilage, waste, and even theft, all of which eat directly into your profit margins. What causes a high DOH? Usually, it’s one of a few culprits:

- Over-ordering: Chasing that bulk discount can seriously backfire if you cannot move the product before it goes bad.

- Shaky Sales Forecasting: If your predictions are off, you end up with a walk-in full of ingredients for dishes nobody is ordering.

- Menu Bloat: A massive, complex menu almost always requires a large, slow-moving, and expensive inventory to support it.

The Risks of a Low DOH

On the flip side, a very low DOH is not automatically a badge of honor. While it shows inventory is turning over fast, it can also mean you’re running dangerously lean. This puts you one busy Saturday night away from stockouts and having to 86 a popular dish.

Nothing frustrates a loyal customer faster than hearing their favorite item is off the menu. A consistently low DOH might mean you’re understocked, leaving money on the table when demand spikes. Finding that sweet spot is the name of the game, and your DOH is a critical piece of that puzzle. For a closer look at other key metrics, check out our guide on the top restaurant KPIs every manager should track.

The “right” DOH is not a universal number. It is about finding the optimal balance for your specific menu, supplier reliability, and sales velocity. What works for a pizzeria is different from what works for a fresh seafood spot.

Finding Your Ideal DOH

Industry benchmarks are a decent place to start. A fast-casual or QSR might aim for a DOH between 4 and 8 days, reflecting their need for fresh ingredients and rapid turnover. A full-service or fine-dining restaurant, however, might be perfectly healthy with a DOH of 15 to 30 days because they’re dealing with more expensive, slower-moving items.

Use these as a guide, not a gospel. Your goal is to track your own DOH over time and watch for trends. Is the number creeping up month after month? Time to look at your purchasing habits. Is it so low that you’re constantly running out of key items? You might need to adjust your order pars before you start losing customers.

Interpreting Your Restaurant’s DOH Results

To make it even simpler, here’s a quick guide to understanding what your DOH might be signaling about your restaurant’s operational health.

| DOH Value | What It Could Mean | What to Do Next |

|---|---|---|

| Below 4 Days (Very Low) | You might be under-ordering, risking stockouts and lost sales. Your team could be stressed trying to manage low pars. | Review your order pars for top-selling items. Talk to your suppliers about delivery frequency. Are you missing sales opportunities? |

| 4 to 8 Days (Lean and Efficient) | This is often the sweet spot for QSRs and high-volume concepts. Cash is not tied up, and spoilage is low. | Keep monitoring. This is a great target, but ensure you are not sacrificing quality or running out of items during unexpected rushes. |

| 8 to 15 Days (Healthy for Full-Service) | A common range for restaurants with more diverse menus. Inventory levels are manageable and balanced against sales. | Analyze your inventory mix. Are there specific categories (e.g., dry goods, proteins) driving the number up? Can you optimize? |

| 15 to 30 Days (High for most, OK for Fine-Dining) | It could be normal if you cellar wine or age proteins. For others, this signals over-ordering, slow-moving items, or menu issues. | Do a deep dive. Identify dead stock and slow-moving items. Consider menu engineering to feature items using this inventory. |

| Above 30 Days (Warning Sign) | Your cash is tied up in inventory that is not selling. High risk of spoilage, waste, and a serious drag on profitability. | Immediate action is required. Liquidate slow-moving stock, review all purchasing processes, and simplify your menu. |

Ultimately, your DOH is not just a number to report. It’s a tool to help you ask better questions. Use it to spark conversations with your chef and BOH team to make smarter, more profitable decisions every week.

Actionable Strategies to Optimize Your DOH

Knowing your Days on Hand is the first step. Turning that number into action is where you actually start to see changes in your cash flow and profits. A lower DOH means you’re running a leaner, more efficient operation. Let’s get into the proven, practical strategies you can use right away to make your inventory work smarter for you.

Master Your Stock Rotation

Sometimes the simplest changes deliver the biggest results, and that’s definitely true for stock rotation. If you’re serious about cutting waste, a strict first-in, first-out (FIFO) system is not just a good idea; it’s nonnegotiable.

When a new delivery comes in, your team needs to get in the habit of putting the fresh items behind the older ones. Every single time. This forces you to use stock in the correct order and drastically cuts down on spoilage and write-offs. A simple label with the delivery date can make this process foolproof, turning a good practice into a daily habit. This one organizational tactic is one of the most effective ways to lower your inventory days on hand formula result.

Fine-Tune Your Purchasing and Delivery Schedule

Over-ordering is the number one reason for a high DOH. Sure, those bulk discounts look tempting, but they often just lead to cash getting tied up in stock that sits on a shelf for weeks. The goal is smarter, more frequent purchasing based on real data.

- Negotiate More Frequent Deliveries: Have a conversation with your key suppliers. Can you get smaller deliveries twice a week instead of one massive drop? This keeps fewer products on your shelves at any given time, which immediately lowers your DOH and improves freshness.

- Analyze Sales Data for Forecasting: Dive into your POS data. Get to know your best-sellers and your slowest-moving items. Adjust your purchasing pars to reflect what your customers are actually ordering, not what you think they will order. A data-driven approach removes the guesswork and stops your walk-in from becoming a graveyard for unpopular ingredients.

- Implement a Reorder Point System: Stop ordering on a whim. Establish clear reorder points for your key inventory items. A reorder point is simply the minimum stock level an item can hit before you must place a new order. It is a disciplined approach that prevents both stockouts and overstocking.

Optimizing inventory is not just about saving money on food costs. It’s about freeing up capital that can be reinvested into other areas of your business, like marketing, staff training, or equipment upgrades.

Embrace Technology and Smart Menu Design

Manual inventory counts are a recipe for human error and suck up valuable time. Modern tools and a little strategic thinking can streamline this whole process and give you a much clearer picture of your inventory health.

If you really want to put these strategies on autopilot, consider implementing a robust restaurant inventory management system. These platforms connect directly with your POS to give you real-time data, automate ordering, and even calculate your DOH for you.

You should also take a hard look at your menu. A big, complex menu demands a massive and expensive inventory. By engineering a leaner menu that cross-utilizes ingredients across multiple dishes, you can significantly slash the number of SKUs you need to keep on hand. This not only crushes your DOH but also makes life easier for your kitchen team. Focusing on sound financial habits is crucial for long-term success, and you can explore more on the key financial habits of successful restaurant operators to guide your strategy.

Common Questions About Inventory Days on Hand

Even after you have a handle on the inventory days on hand formula, real-world questions always pop up. Things get tricky when you apply the math to the beautiful chaos of a real kitchen.

We have compiled a few frequently asked questions to help you fine-tune your inventory management skills.

How often should I calculate DOH?

For most restaurants, calculating DOH monthly is the gold standard. It lines up perfectly with your P&L statements and other financial check-ins, giving you a steady rhythm for tracking inventory efficiency.

But if you are dealing with a lot of highly perishable ingredients like fresh seafood, delicate produce, or artisan cheeses, a weekly calculation can be a game-changer. It helps you spot over-ordering and waste before it turns into a real problem, letting you adjust on the fly instead of waiting until the end of the month.

How does seasonality affect my DOH calculation?

Seasonality will absolutely make your DOH numbers swing. A waterfront spot is going to stock up for a slammed summer, so its DOH will naturally spike in June and July. Trying to compare that to a quiet February is like comparing apples to oranges.

The key is to compare your DOH year-over-year. Look at this July versus last July. That gives you a much truer read on whether your purchasing is getting more efficient. This approach smooths out those predictable seasonal bumps and shows you what is really changing.

Is it possible for my DOH to be too low?

Absolutely. While running lean is the goal, an extremely low DOH is a major red flag. It is a sign that you’re understocked and flying too close to the sun.

A DOH that is too low means you are one busy service away from having to 86 a popular dish. That leads to disappointed guests and lost sales. Research shows that stockouts can seriously ding customer loyalty and how people see your brand.

If your DOH is consistently in the danger zone, it is time to rethink your ordering pars. You might need to build in a small safety stock for critical items or find suppliers who can guarantee faster, more reliable deliveries. The goal is not just to be lean. It is to be lean and ready.

What tools can help me track and calculate DOH?

You can definitely get by with a well-organized spreadsheet, but modern tech makes this a lot easier. The best tool for the job is an inventory management system that plugs directly into your Point of Sale (POS) system.

These platforms do the heavy lifting for you, tracking sales and inventory levels in real-time. This pretty much eliminates the manual data entry and the human error that comes with it. Many systems even have dashboards that calculate DOH for you, freeing you up to focus on making smart decisions instead of crunching numbers.

Ready to turn these insights into action and run a smarter, more profitable restaurant? At MAJC, we provide hospitality operators with the tools, training, and community support needed to master everything from inventory control to team leadership. Join MAJC today and start building a more sustainable and successful business.