Cutting down on food waste is one of the single most powerful levers you can pull to boost your restaurant’s profitability. It is not just about the cost of the food you toss; waste is a silent killer that drains labor, energy, and water, turning black ink into red. This is not just an environmental feel-good—it is a critical financial strategy.

The Hidden Costs of Restaurant Food Waste

When an unsold special hits the bin, the loss feels obvious. You paid for ingredients that never made it to a customer’s plate. But the real financial gut punch of food waste runs much deeper, weaving its way through nearly every corner of your operation.

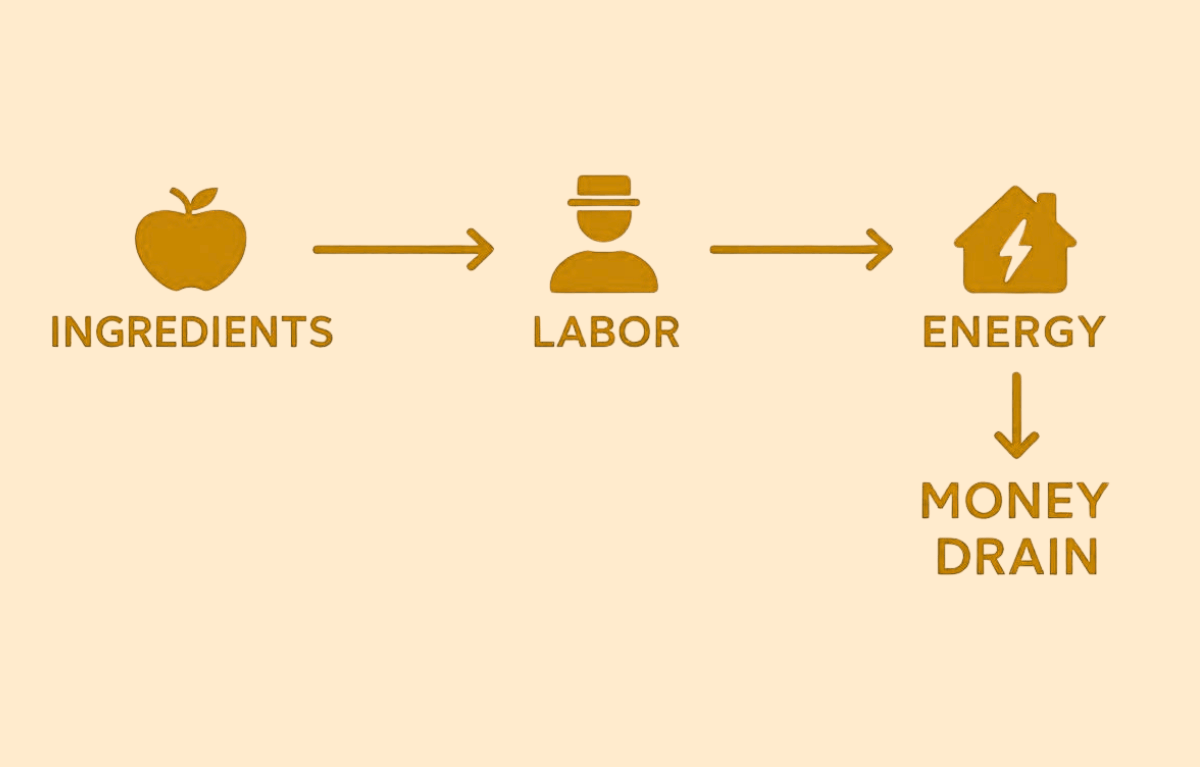

For every pound of food you throw out, you are also throwing away the money spent on the labor to prep it, the gas or electricity used to cook and store it, and the water to wash it. These are sunk costs that just vanish, with zero return on investment.

More Than Just Missing Ingredients

Think about it this way: that big batch of soup you prepped that did not sell is not just wasted carrots and stock. It represents:

- Labor Costs: The time your prep cook spent peeling, chopping, and simmering.

- Energy Costs: The gas burned by the stove and the electricity humming from the walk-in to keep everything cold.

- Opportunity Costs: The precious walk-in space it hogged could have been used for ingredients for one of your best-selling dishes.

These costs stack up, turning what seems like a small daily loss into a massive financial leak over the course of a year. That is why you have to start seeing waste reduction as a core business strategy, not just a back-of-house chore.

Food waste in restaurants is more than an operational frustration; as we mentioned earlier, it’s a direct hit to your bottom line. According to ReFED’s 2025 U.S. Food Waste Report, Americans waste nearly 35 million tons of food every year across households and restaurants, representing billions in lost value. For operators, restaurant plate waste is a meaningful slice of that total, amplifying the financial impact because every discarded item reflects sunk labor, energy, and storage costs that can never be recovered.

The True Price of Overstocking

Holding on to too much inventory comes with its own set of hidden fees. We all know the direct cost of spoilage, but many operators forget about the other financial burdens. These inventory carrying costs include extra storage expenses, insurance, and the constant risk of spoilage, all of which quietly chip away at your profits.

Getting a handle on how these costs impact your operation is the first step. To see the full picture, tools like a restaurant profit margin calculator can be a real eye-opener. When you accurately measure your expenses against your revenue, you start to see just how much waste is truly costing you.

Get Real: How to Run a Practical Food Waste Audit

You cannot fix what you do not measure. If you are serious about cutting food waste, you have to know exactly what is being tossed, how much, and why. Guesswork just will not do it. A food waste audit is your diagnostic tool; it gives you the hard data to turn vague concerns into a concrete action plan.

This does not have to be some complicated, disruptive process that grinds your kitchen to a halt. It is simply about creating a system to see your waste streams clearly. Once you make it a habit, you will have the intel to make targeted changes that actually hit your bottom line.

Setting Up a Simple Tracking System

The goal here is to make tracking waste dead simple for your team. Start by setting up designated, clearly labeled bins in key spots: the prep station, the line, and the dish pit. Do not overcomplicate it.

I recommend sorting waste into three main buckets:

- Spoilage: This is food that went bad before you could even use it. Think wilted herbs, moldy produce, or expired dairy. This almost always points back to over-ordering, poor stock rotation, or improper storage.

- Prep Waste: All the trimmings, peels, and scraps from butchery and veg prep. Some of this is unavoidable, but a bin overflowing with trim might signal a need for better knife skills or a huge opportunity to repurpose scraps into stocks, sauces, or specials.

- Plate Waste: This is the goldmine of customer feedback. It is all the food that comes back uneaten from the dining room. A pile of leftover fries is a direct signal that your portion sizes are probably too big. A half-eaten steak special tells you the dish just is not hitting the mark.

Stick a simple log sheet or a tablet right next to the bins. At the end of each shift, a designated person weighs each bin’s contents and logs the weight, the waste type, and a quick note. For example: “10 lbs spoiled lettuce,” “5 lbs steak trim,” or “8 lbs leftover fries.”

A waste audit is like a financial check-up for your kitchen. It takes you from thinking you know where your waste comes from to knowing for sure. That lets you plug the most expensive leaks first.

Analyzing the Data to Find Your Biggest Leaks

After a week or two of tracking, the patterns will jump right out at you. Is the spoilage bin always full of cilantro and parsley? You are likely ordering too much or need a supplier who can do smaller, more frequent drops.

This data-first approach works. The mere act of measuring and reporting food waste pushes businesses to adopt better practices, leading to real reductions. It is a classic case of what gets measured gets managed.

Make the Audit a Team Sport

Look, a food waste audit will fail if it is just a top-down mandate. Your team has to be on board. Take the time to explain the why behind it. Frame it as a shared mission to make the restaurant more profitable, sustainable, and frankly, a better place to work.

When your crew understands that cutting waste helps keep the business healthy and secures their jobs, they become your eyes and ears on the floor. Their insights are invaluable. The line cook who sees the same box of spring mix wilt every week, or the server who hears every guest say the burger is “huge,” can give you the context that the numbers alone cannot.

Smarter Menu Design and Inventory Control

Your food waste audit showed you where the waste is happening. Now it is time to dig into the why. The numbers you just crunched point directly to two of the most powerful levers in your entire operation: your menu and your inventory.

These two are deeply connected. Making small, smart adjustments here can have a massive impact on your bottom line, creating a system where what you buy gets used efficiently in what you sell. This is how you get ahead of spoilage and over-ordering before they ever get a chance to drain your profits.

Engineer Your Menu for Maximum Efficiency

Think of your menu as the blueprint for your kitchen, not just a list of dishes. A well-designed menu is your single greatest weapon in the fight against waste. The goal is simple: build a menu where ingredients pull double or triple duty, ensuring everything you order moves.

This strategy is called cross-utilization, and it is a game-changer. Instead of buying a specialty ingredient for one dish that might not sell, you design recipes that share core components.

For example, if you bring in cilantro for a salsa, make sure that same cilantro shows up in a marinade, a soup, and as a garnish. This simple mindset shift dramatically increases the turnover of that ingredient, making spoilage far less likely. It is all about building versatility directly into your offerings.

Smart Portioning and Flexible Offerings

All that plate waste you measured in your audit? That is direct feedback from your guests. If you are consistently seeing piles of uneaten food, it is a clear sign that your portion sizes are too generous.

Consider offering dishes in multiple sizes. A half portion of pasta or a smaller lunch-sized salad not only cuts down on plate waste but also gives guests more control and a better sense of value. This kind of flexibility appeals to a wider range of appetites and budgets, all while keeping food out of the bin.

A smart menu does not try to be everything to everyone. It focuses on doing a few things exceptionally well, using a core group of ingredients that move quickly from shelf to plate.

Master Your Inventory with Proven Methods

With a waste-efficient menu locked in, you can bring real precision to your purchasing and storage. Effective inventory control is not about being cheap; it is about having exactly what you need, when you need it, and nothing more.

This is where a few time-tested methods make all the difference.

Two practices should be nonnegotiable in any professional kitchen:

- First-In, First-Out (FIFO): This is the golden rule of stock rotation. It is a dead-simple system: old stock always goes to the front, and new stock to the back. This ensures ingredients get used in the order they were received, which drastically cuts the risk of spoilage and expired products.

- Set Realistic Par Levels: A par level is the minimum amount of an ingredient you need on hand to get through service. By analyzing your sales data, you can set realistic pars for every single item you stock. This data-driven approach stops over-ordering in its tracks and frees up cash and cooler space.

Keeping a close watch on your stock levels is crucial. A key metric many operators use is inventory days on hand, which tells you how long your current inventory will last. You can dive deeper into how to calculate and apply the inventory days on hand formula to make even sharper purchasing decisions.

Build Stronger Supplier Relationships

Finally, remember that your suppliers can be powerful allies in your mission to reduce food waste. Do not be afraid to have a real conversation with them about your goals. Many are willing to find solutions that benefit you both.

Ask about the possibility of more frequent, smaller deliveries. Yes, you might lose a small bulk discount, but the savings from eliminating spoilage almost always outweigh it. This “just-in-time” approach keeps your inventory lean and your ingredients at peak freshness, ensuring what you buy actually turns into revenue.

If you want to go deeper into how world-class operators tackle food waste, check out our podcast episode with Chef Manu Bufara. She shares practical, real-life strategies for reducing waste in the kitchen, including how stronger relationships with suppliers can transform the way you purchase, prep, and use ingredients. It’s a powerful conversation for anyone serious about building a more sustainable and efficient restaurant.

Using Technology to Fight Food Waste

Experience matters in the kitchen, but technology is what truly moves the needle on waste. Manual tracking and spreadsheets only get you so far; digital tools give you real-time data to make faster, smarter decisions that protect your margins.

Think of tech not as an expense, but as an investment. With the right systems, you go from guessing to knowing, transforming how you manage inventory, prep, and purchasing.

Embrace Smart Inventory Management

Clipboards and late-night counts are outdated. Modern inventory software gives you a live, accurate view of what you have, what you’re using, and what you need next. Integrated with your POS, it automatically adjusts ingredient levels as orders are closed.

This level of precision is impossible to achieve manually. You’ll know exactly which ingredients move quickly, and which don’t, so you can adjust purchasing on the fly. Many tools even alert you when items run low or are nearing expiration, helping you avoid both stockouts and spoilage. It’s a complete game-changer for reducing food waste in restaurants.

Get Granular with Waste Tracking Systems

Smart waste-tracking systems go far beyond inventory, they show you exactly what’s landing in the trash and why. Using scales, cameras, and quick on-screen tagging, these tools automatically record spoilage, prep trim, and plate waste in real time.

The insights are incredibly actionable. You might learn that a side dish comes back uneaten half the time or that the team is trimming far too much off certain ingredients. This kind of data helps you refine recipes, right-size portions, and tighten prep practices.

By clearly connecting waste to its financial impact, these systems make it easy to target the biggest leaks and unlock immediate savings.

For a bigger picture on how these tools fit into your overall strategy, take a look at our guide on how to improve restaurant operations.

Nail Your Prep with AI-Powered Forecasting

One of the oldest, most frustrating sources of waste is the mismatch between what you prep and what you sell. You staff up and prep for a huge Saturday night, only to watch a thunderstorm wash it out. All that beautiful food? Straight to the bin.

Artificial intelligence (AI) is finally cracking this code by delivering incredibly accurate demand forecasts. AI platforms dig into your historical sales data and layer in outside variables like weather, local events, holidays, and even your own marketing promotions. The system then predicts, with surprising accuracy, how many of each dish you are likely to sell on any given day.

This kind of predictive power lets your kitchen team:

- Prep with purpose: Stop prepping for the “just in case” and start prepping for what is actually likely to sell.

- Order smarter: Base your purchasing on data-driven forecasts, not last week’s sales report and a hunch.

- Staff efficiently: Align your labor schedule with predicted customer traffic, so you are never over or understaffed.

When your prep and purchasing are synced up with actual demand, the risk of spoilage and dead inventory plummets. Your whole operation gets leaner, smarter, and way more profitable.

Here is a quick look at how different technologies can help you tackle waste from multiple angles.

Key Technologies for Restaurant Waste Reduction

| Technology Type | Primary Function | Key Benefits |

|---|---|---|

| Inventory Management Software | Real-time tracking of stock levels, automated depletion via POS integration, and low-stock/expiration alerts. | Reduces over-ordering, minimizes spoilage, prevents stockouts, and saves significant labor on manual counts. |

| Waste Tracking Systems | Automated logging of discarded food (spoilage, prep, plate waste) using scales, cameras, and analytics. | Identifies top sources of waste, provides data for menu engineering, and helps refine prep techniques. |

| AI Demand Forecasting | Predicts future sales based on historical data, weather, events, and other variables to guide prep and ordering. | Minimizes over-preparation, reduces spoilage of unsold food, and optimizes staffing levels. |

| Digital Kitchen Checklists | Standardizes prep lists, temperature logs, and cleaning schedules to ensure consistency and prevent spoilage. | Improves food safety, reduces errors that lead to waste, and ensures FIFO procedures are followed. |

Ultimately, these tools work together to create a more informed, efficient, and profitable kitchen. They replace guesswork with data, allowing you to make proactive decisions that cut costs and build a more sustainable operation.

Building a Waste-Conscious Kitchen Culture

You can refine your menu and tighten your inventory, but none of it sticks unless your team is fully aligned. Waste reduction isn’t just a system, it’s a mindset. And it only works when everyone, from the dishwasher to the GM, understands why it matters.

When waste becomes a shared mission instead of another rule, employees shift from passive participants to active partners. That’s how you build a kitchen culture that protects both your margins and the environment.

Empower Your Team Through Hands-On Training

A waste-conscious culture starts with training that’s practical, specific, and tied directly to daily tasks. The goal isn’t to tell people to “waste less”, it’s to give them the skills to make smarter decisions in the moment.

For BOH teams, focus on training that boosts yield:

-

Knife Skills: Teach prep cooks to supreme citrus, break down cauliflower efficiently, or filet fish with minimal loss. Small improvements add up fast.

-

Smart Storage: Reinforce proper herb storage, walk-in organization using FIFO, and vacuum-sealing techniques to extend shelf life.

-

Creative Use of Scraps: Run quick workshops to repurpose trim, crisp vegetable peels for garnishes, herb stems for infused oils, or meat scraps for standout staff meals. This builds creativity and a true waste-not mindset.

When you standardize your methods, you get consistent results. For some great examples of how to structure this kind of documentation, check out our guide to restaurant standard operating procedures examples.

Turn Your FOH Team into Waste Ambassadors

Your front-of-house team is your direct link to guests, and one of your strongest tools for reducing food waste. When servers understand which dishes commonly come back unfinished, they can set expectations before orders are placed.

A quick heads-up like, “Our ribeye is a hearty 16-ounce portion, it’s delicious but definitely a big meal!” helps guests choose portions they’ll actually finish. It improves the dining experience and prevents unnecessary waste.

When FOH staff feel ownership over waste reduction, they become active partners in protecting your food cost and enhancing service.

Keep the Momentum with Creative Incentives

Training alone won’t sustain a waste-focused culture; incentives help keep the team engaged and motivated.

Here are simple, high-impact ideas:

-

Team Challenges: AM vs. PM to hit the lowest weekly waste percentage. Rewards can be small but meaningful: a team meal, preferred parking, or bragging rights.

-

Share the Savings: Show the team how their efforts reduce costs. When you hit a monthly target, share a portion of the savings as a bonus.

-

Celebrate Champions: Recognize employees who consistently follow best practices or come up with smart ways to repurpose ingredients. A “Waste Warrior” or “Sustainability Champion” shout-out builds pride and momentum.

When staff feel recognized and connected to the results, waste reduction becomes something they want to participate in, not just another rule to follow.

Creative Solutions for Unavoidable Food Scraps

Even in the most dialed-in kitchen, some food scraps are just part of the deal. The real opportunity is not eliminating them entirely; it is changing how you see them. This is where you shift from a “waste” mindset to a “resource” mindset and find responsible, often profitable, alternatives to the landfill.

The first stop for any surplus should be people, not dumpsters. A surprising amount of what restaurants toss is perfectly good, edible food.

Partnering with local food banks or rescue organizations like Food Rescue US makes it dead simple to donate safe, unserved food. Many of these groups even handle the pickup logistics, and federal laws like the Bill Emerson Good Samaritan Food Donation Act are in place to protect your business from liability.

Turn Scraps Into Revenue

Thinking creatively about scraps is a core part of reducing food waste in restaurants. It is not just about saving money on disposal; it is about generating new value from ingredients you have already paid for.

Here are a few practical ideas to get the wheels turning:

- Stocks and Broths: Those onion peels, carrot tops, and herb stems are pure flavor. Simmer them down into a rich, house-made vegetable or bone broth that becomes the backbone of your soups, sauces, and risottos.

- Infusions and Syrups: Citrus peels can be candied for garnishes or used to infuse spirits for signature cocktails. Strawberry tops? They make a fantastic simple syrup for drinks or desserts.

- Crispy Garnishes: Do not toss those potato peels. Fry them up, season them well, and you have got an addictive bar snack or a crunchy topping for soups and salads.

Closing the Loop with Composting

Once you have exhausted all your donation and upcycling options, composting is the final, responsible move. When organic matter rots in a landfill, it produces methane, a highly potent greenhouse gas. Composting, on the other hand, turns those scraps back into nutrient-rich soil.

Many cities now offer commercial composting services designed for restaurants, making it easier than ever to keep what is left out of the landfill. It is the last step in your waste hierarchy, reinforcing your commitment to sustainability and closing the loop on your food’s lifecycle.

Common Questions About Restaurant Food Waste

Even with the best playbook, you are going to hit roadblocks. That is just part of the process. The operators who succeed are the ones who anticipate the common hurdles and know how to clear them without losing momentum.

Here are the questions that come up most often and some straight answers from the field.

Where Should I Start if My Budget Is Limited?

You don’t need expensive software to reduce food waste. Start with a simple manual audit: set up labeled bins (prep waste, spoilage, plate waste) and track what you throw out for a week. This low-cost step gives you the data you need to identify your biggest leaks.

Once you see the patterns, many of the fixes are free, adjusting a dish that comes back half-eaten, tightening receiving habits, or refreshing knife skills to improve yield.

How Do I Get My Staff to Care About Food Waste?

Waste reduction only works when your team understands why it matters. Share the numbers from your audit and show the real cost of wasted ingredients, labor, and energy. Reinforcing progress with team rewards or reinvesting a portion of savings can build buy-in fast.

Training should be hands-on and relevant. When cooks see how better technique increases usable product, or servers realize how one clarifying question prevents a returned dish, they become true partners in reducing waste.

Is It Complicated to Donate Surplus Food?

Not at all. Liability concerns stop many operators, but the process is simpler than ever. Organizations like Food Rescue US and local food banks streamline donation, manage logistics, and provide the documentation you need. Safe, unserved food can be redirected quickly, reducing waste while supporting your community.

Building a profitable and sustainable restaurant requires the right tools and a supportive community. At MAJC, we provide operators with the training, systems, and expert guidance to run smarter operations, from cutting costs to developing a world-class team. Discover how MAJC can help you build a better business.